Hucklok®

Call 0800 748 832 or email sales@rivtec.co.nz for a quote

HuckLok® Blind Rivet: Strength You Can Rely On

The HuckLok® blind rivet is engineered for superior performance, featuring a wide grip range and an innovative double-locking action. This unique design secures the assembly from both sides, delivering maximum holding power and exceptional joint integrity. With a large blind-side footprint, HuckLok® prevents pull-through, making it ideal for thin, lightweight, or pliable materials like plastics, composites, and more.

Key Features:

-

Unique Bulbing System: Enhances blind-side strength for a stronger, more reliable hold.

-

Wide Grip Range & Double-Locking Action: Secures both sides for maximum stability.

-

Positive Mechanical Bolt Retention: Maintains structural integrity under stress.

-

Large Blind-Side Footprint: Prevents pull-through on delicate materials.

-

Annular Grooves: Maintain consistent pressure on the backside for lasting durability.

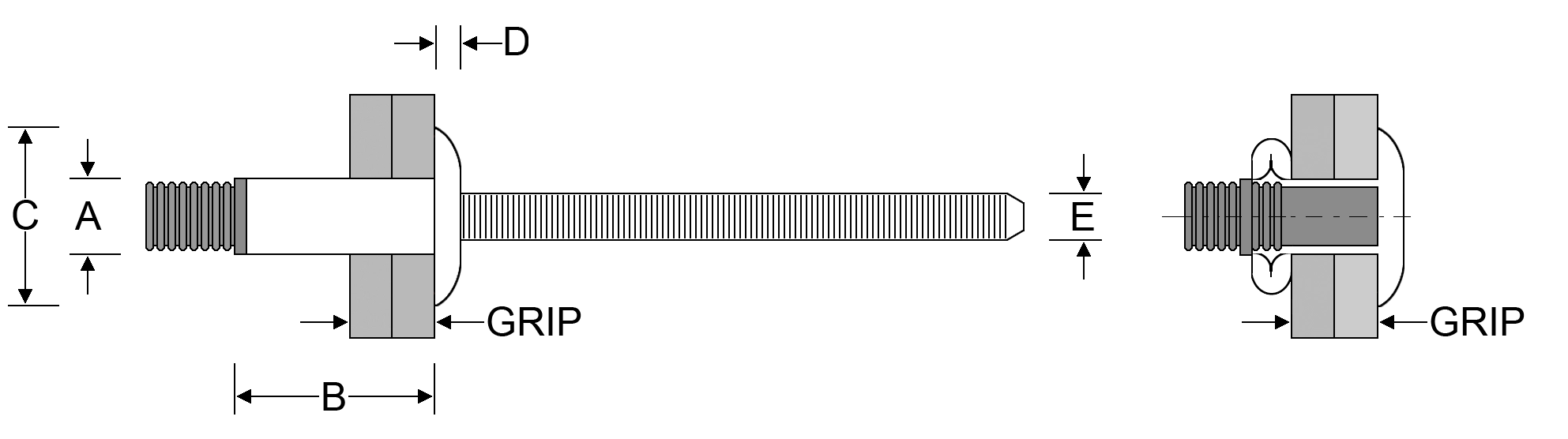

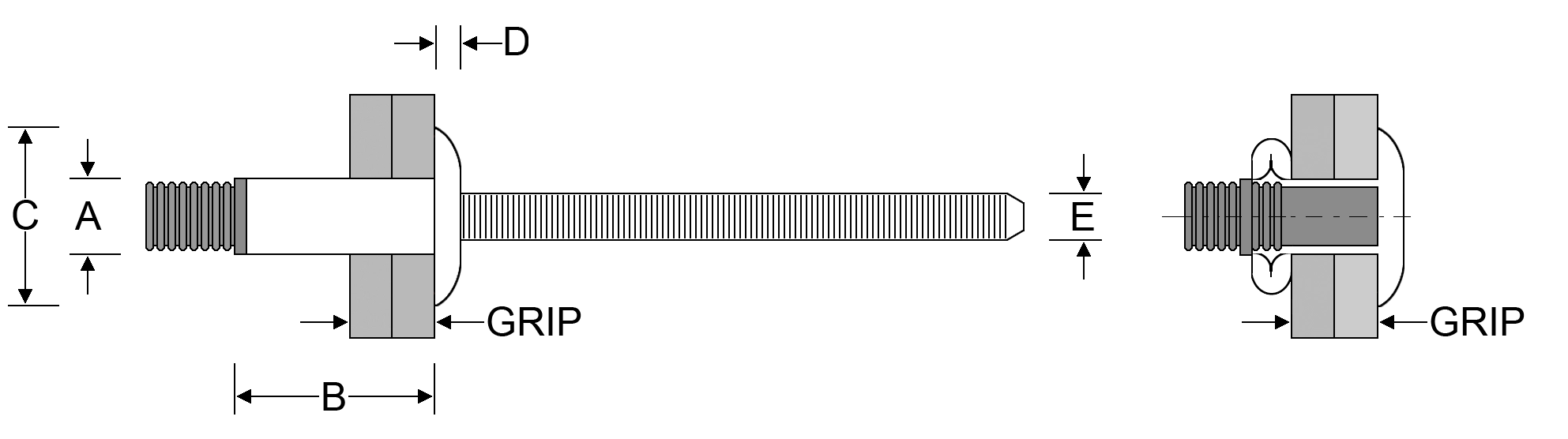

Rivet Measurement Method and Post Install Sequence

A = Rivet Diameter | B = Rivet Length | C = Head Diameter | D = Head Thickness | E = Mandrel Diameter

For more information and technical data click on the Product Download, free phone in NZ 0800 RIVTEC or email sales@rivtec.co.nz

Description

HuckLok® Blind Rivet: Strength You Can Rely On

The HuckLok® blind rivet is engineered for superior performance, featuring a wide grip range and an innovative double-locking action. This unique design secures the assembly from both sides, delivering maximum holding power and exceptional joint integrity. With a large blind-side footprint, HuckLok® prevents pull-through, making it ideal for thin, lightweight, or pliable materials like plastics, composites, and more.

Key Features:

-

Unique Bulbing System: Enhances blind-side strength for a stronger, more reliable hold.

-

Wide Grip Range & Double-Locking Action: Secures both sides for maximum stability.

-

Positive Mechanical Bolt Retention: Maintains structural integrity under stress.

-

Large Blind-Side Footprint: Prevents pull-through on delicate materials.

-

Annular Grooves: Maintain consistent pressure on the backside for lasting durability.

Rivet Measurement Method and Post Install Sequence

A = Rivet Diameter | B = Rivet Length | C = Head Diameter | D = Head Thickness | E = Mandrel Diameter

For more information and technical data click on the Product Download, free phone in NZ 0800 RIVTEC or email sales@rivtec.co.nz

Reviews (0)

Be the first to write a review